The Importance of Foundry Services in Quality Metal Manufacturing

Foundry solutions hold a vital position in the domain of metal fabrication. They support the conversion of raw materials into high-quality components through accurate casting and molding methods. Skilled professionals are essential in this operation, as they aim to eliminate defects and maintain rigorous testing. Understanding how these services influence overall product quality provides insight into their broader implications in manufacturing efficiency and market competitiveness. What lies beyond this initial foundation?

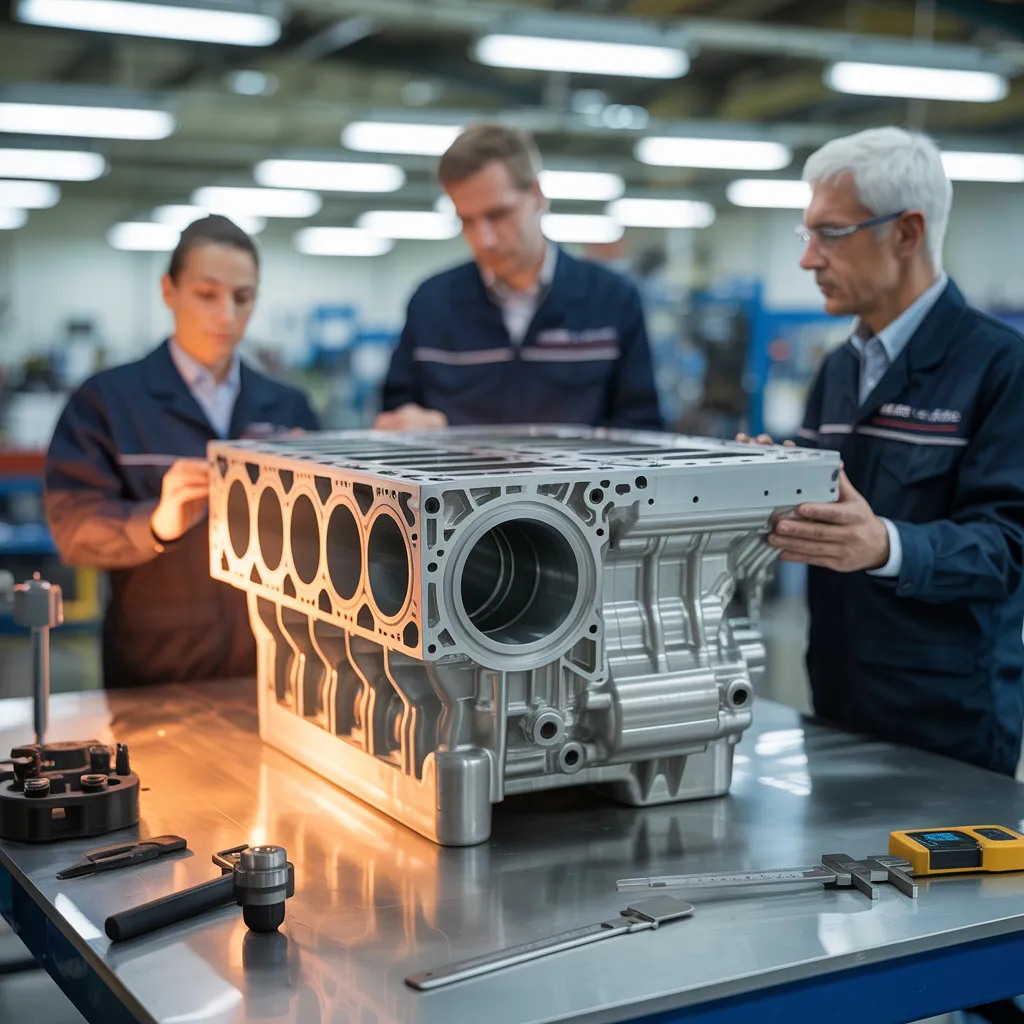

Understanding the Fundamental Role of Foundry Services in Metal Manufacturing

Though numerous people might disregard the importance of foundry services, they serve a critical role in the metal manufacturing industry. Foundry services involve numerous processes, including casting, molding, and finishing, which are vital for creating high-quality metal components. These services assist the transformation of raw materials into usable forms, enabling manufacturers to create intricate shapes and designs that comply with specific industry standards.

In addition, foundry services enable the production of a wide range of metals, like aluminum, steel, and bronze, with each needing specialized techniques and expertise. The precision obtained through these services not only enhances the performance of final products but also supports the overall efficiency of manufacturing operations. By understanding the fundamental role of foundry services, stakeholders in the metal manufacturing sector can understand how these processes form the foundation for the creation of consistent, durable components, ultimately influencing the success of various applications in different industries.

Top Benefits of Foundry Services for Maintaining Quality Control

Foundry services substantially boost quality control in metal manufacturing, as they employ exact techniques and demanding standards throughout the production process. One of the primary benefits is the expertise of skilled professionals who oversee every stage, maintaining adherence to specifications and reducing defects. In addition, foundry services employ comprehensive testing methods, including dimensional evaluations and material analysis, which authenticate the quality of the created components.

Another significant advantage is the use of cutting-edge materials and techniques tailored to specific applications, which leads to better durability and performance of the final products. Consistency is also realized through established protocols that reduce variability, maintaining uniformity in production.

Additionally, foundry services facilitate efficient feedback loops, facilitating swift identification and rectification of issues, therefore improving overall product reliability. Ultimately, these factors contribute to a higher level of customer satisfaction and trust, making foundry services critical for achieving and maintaining quality control in metal manufacturing.

How Does Technology Boost the Benefits of Foundry Services?

Technology significantly enhances foundry services by introducing advanced casting techniques that boost precision and efficiency. Additionally, real-time quality monitoring systems provide immediate feedback and adjustments, making certain that manufacturing standards are consistently met. These technological advancements not only streamline processes but also improve the overall quality of metal products.

Advanced Methods of Casting

As industries evolve, cutting-edge casting technologies surface as a critical component in elevating the benefits of foundry services. These methods, including investment casting, lost foam casting, and 3D printing, employ advanced technology to boost precision and reduce waste. By using sophisticated materials and automated processes, manufacturers can realize complex geometries that were previously unreachable. This not only increases the quality of the final products but also decreases lead times, enabling more rapid market responsiveness. Additionally, these approaches enable customization, empowering clients to secure tailored solutions that fulfill specific requirements. Overall, the adoption of cutting-edge casting technologies substantially streamlines production efficiency and quality assurance, building a competitive edge for foundry services in the metal manufacturing landscape.

Real-Time Performance Oversight

In modern metal manufacturing, the integration of real-time quality monitoring systems substantially boosts the effectiveness of foundry services. These systems utilize advanced sensors and data analytics to continuously assess production processes, ensuring that specifications are met at every stage. By providing prompt feedback, manufacturers can promptly identify and resolve defects, reducing waste and boosting overall efficiency. This proactive approach reduces downtime and improves product quality, ultimately leading to higher customer satisfaction. Additionally, real-time monitoring empowers manufacturers to maintain compliance with industry standards and regulations. As a result, the adoption of these technologies not only optimizes the foundry's operational capabilities but also strengthens its competitive edge in the market.

Elevating Product Durability and Performance Through Foundry Services

As numerous sectors pursue cutting-edge approaches to improve product longevity and functionality, foundry services emerge as an essential component view resource in achieving these objectives. By employing advanced casting techniques and materials, foundries can create components with superior strength and resilience. The use of top-grade alloys and precision casting processes assures that the final products can withstand severe conditions and stresses, substantially extending their lifespan.

Additionally, foundry services include stringent quality control measures throughout the manufacturing process, confirming that each component meets rigorous performance specifications. This meticulous approach not only increases the durability of the products but also maximizes their functionality in diverse applications. Furthermore, custom foundry solutions permit tailored designs that satisfy specific industry requirements, further boosting overall performance. In this way, foundry services play a pivotal role in improving the durability and effectiveness of metal products across multiple sectors, from automotive to aerospace.

Why Investing in Professional Foundry Services Makes Financial Sense

Purchasing professional foundry services can deliver considerable financial benefits for businesses striving to strengthen their manufacturing operations. By harnessing expert knowledge and advanced technical solutions, companies can reduce production costs through increased efficiency and minimized waste. Professional foundries typically provide tailored solutions that optimize the design and manufacturing process, creating superior-quality products that comply with stringent industry standards.

Furthermore, outsourcing foundry services enables businesses to prioritize core competencies, releasing resources for innovation and growth. This strategic investment can also result in faster turnaround times, allowing companies to respond promptly to market demands. Additionally, the expertise of professional foundries can minimize the risk of costly errors, which often stem from inexperienced handling of complex metal formulations. In the end, the financial implications of investing in professional foundry services go beyond immediate cost savings, fostering long-term sustainability and competitive advantage in the manufacturing landscape.

Real-Life Success Stories of Foundry Services in Metal Manufacturing

Success stories are plentiful in the domain of metal manufacturing, showcasing how companies have overhauled their operations through the use of professional foundry services. One notable example is a leading automotive manufacturer that encountered production delays due to inconsistent metal quality. By working with a specialized foundry, they enhanced their supply chain efficiency and significantly reduced defects, resulting in a 30% increase in production output.

Likewise, a machinery manufacturer dealing with high costs and material waste moved to a foundry renowned for its precision casting expertise. This cooperative effort not only lowered material expenses but also elevated product durability, generating a 25% improvement in customer satisfaction ratings.

Such examples highlight that dedicating funds to professional foundry services can lead to significant operational enhancements, cost benefits, and enhanced product quality. Those success stories underscore the vital role that foundry services play in the competitive landscape of metal manufacturing.

Frequently Asked Questions

Which Metals Are Commonly Employed in Foundry Services?

Foundry processes generally use several metals, including aluminum, cast iron, steel, and bronze. These materials are chosen for their particular properties, which enhance the strength, durability, and performance of the final cast products.

How Can I Choose the Right Foundry Service Provider?

To select the right foundry service provider, one should examine their expertise, technology, quality certifications, and customer reviews. Comparing pricing and lead times can also guarantee alignment with specific project requirements and expectations.

What Are the Typical Challenges Encountered in Foundry Services?

Typical challenges in foundry services include irregular material quality, equipment maintenance issues, labor shortages, fluctuating raw material costs, and regulatory compliance. These factors can considerably impact production efficiency and the overall quality of metal castings.

How Long Does the Foundry Process Usually Take?

The foundry procedure generally requires several weeks to months, determined by the complexity of the design, material selection, and manufacturing quantity. Factors such as die preparation and final processing steps can greatly influence the entire duration.

Are Foundry Operations Eco-Friendly?

Foundry services can be eco-friendly when employing sustainable practices, such as reprocessing materials and implementing energy-efficient technologies. However, the overall impact relies on specific processes and adherence to environmental regulations within the industry.